What is Polished Concrete?

Polished concrete is a mechanical grind and polish process that utilizes industrial diamonds & impregnated hardeners and sealers to level, densify, polish & finally seal the floor from within the interior of the concrete surface. We can grind concrete floors whether new or old to any desired gloss providing a lasting low maintenance floor.

Polished concrete floors are unique because the aggregate exposure differs in every install. No two floors are exactly alike and only get better with age. Superior durability in addition to its extensive life cycle and cost efficiency, polished concrete floors offer many benefits such as energy efficiency, longer life cycle, allergen-friendly, reduced maintenance, resistance to high foot traffic, high light reflectivity, environmentally friendly and easy to maintain.

From showrooms to industrial plants, commercial and retail stores, government buildings, warehouses, schools, to residential homes and condo's polished concrete is one of the most innovative, economical, and environmentally friendly flooring options available today.

Homeowners are also quickly catching on to the appeal of smooth, high-luster floors, which can be stained to replicate the look of polished stone. Any structurally sound concrete floor, new or old can be polished to a high-gloss finish that never needs waxes or coating.

Polished concrete floors are unique because the aggregate exposure differs in every install. No two floors are exactly alike and only get better with age. Superior durability in addition to its extensive life cycle and cost efficiency, polished concrete floors offer many benefits such as energy efficiency, longer life cycle, allergen-friendly, reduced maintenance, resistance to high foot traffic, high light reflectivity, environmentally friendly and easy to maintain.

From showrooms to industrial plants, commercial and retail stores, government buildings, warehouses, schools, to residential homes and condo's polished concrete is one of the most innovative, economical, and environmentally friendly flooring options available today.

Homeowners are also quickly catching on to the appeal of smooth, high-luster floors, which can be stained to replicate the look of polished stone. Any structurally sound concrete floor, new or old can be polished to a high-gloss finish that never needs waxes or coating.

Benefits

Polished conrete is ideal for large warehouses, auto showrooms, hotels and restaurants, office buildings, private residences, government building and more.

For Residential Floors

Cost Savings

Compared to conventional floor coverings there are no added costs for prep and install. Longer life-cycle savings: Polished floors are extremely durable and do not need to be replaced.

For Commercial & Retail Polished Floors

Additional Savings

Using the existing slab as the finished floor is more cost effective and maintenance costs are lower.

Maintenance is easier since all areas are one continuous surface. - concrete floors are a very hard wear surface with high resistance to foot traffic and can stand up to the everyday wear and tear of retail or industrial work spaces.

Maintenance is easier since all areas are one continuous surface. - concrete floors are a very hard wear surface with high resistance to foot traffic and can stand up to the everyday wear and tear of retail or industrial work spaces.

Less Maintenance & Longer Service Life

Polished floors are easy to clean, requiring only occasional damp mopping or floor maintainers with a neutral based cleaner. They eliminate the need for messy waxes or coatings as well as the expenses involved in applying them.

Mechanically polished concrete resists the marks of forklift truck tires and staining from oil and chemical spills.

Mechanically polished concrete resists the marks of forklift truck tires and staining from oil and chemical spills.

Resistant to Moisture Transmission

Polished concrete allows the floor to breathe and eliminates issues that arise with other flooring materials that seal off the concrete, such as Paint, Vinyl tile etc.

High Light Reflectivity

Important for facilities that want to project a bright, clean, professional image. Also saves energy by reducing artificial lighting requirements

Is A Sustainable Flooring Alternative

Concrete floors do not require hazardous coatings, cleaners or adhesives

Types of Polished Concrete

The different types of polished concrete floors are designed so you can have more than just a glossy floor.

From a cream finish to a heavy exposed finish, polished concrete is by far one of the most beautiful floors in the world. Not only is it durable, but it can literally last a lifetime.

There's more to a polished concrete floor than just a beautiful glossy floor. Aside from stained polished concrete, you can also choose the type of polished concrete finish you want. If you want a specific type of aggregate (Glass, metal, big rocks, etc.) it can be achieved in the pouring stage prior to the polishing as it will be new concrete.

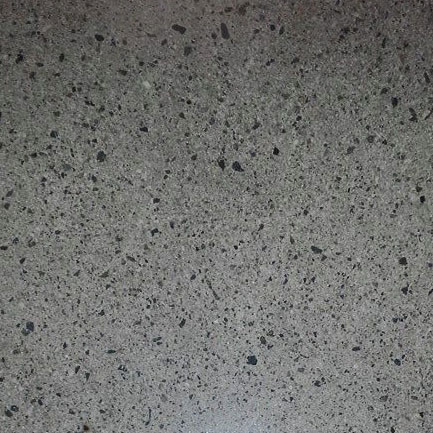

There are different levels of exposure when it comes to polished concrete floors. The depth of the grind, or how much of the top of the concrete slab is removed will determine how much aggregate (or stone) is exposed. While there are different variations of each (such as color), salt and pepper, sporadic rock, medium rock, or heavy rock exposed are the most common.

From a cream finish to a heavy exposed finish, polished concrete is by far one of the most beautiful floors in the world. Not only is it durable, but it can literally last a lifetime.

There's more to a polished concrete floor than just a beautiful glossy floor. Aside from stained polished concrete, you can also choose the type of polished concrete finish you want. If you want a specific type of aggregate (Glass, metal, big rocks, etc.) it can be achieved in the pouring stage prior to the polishing as it will be new concrete.

There are different levels of exposure when it comes to polished concrete floors. The depth of the grind, or how much of the top of the concrete slab is removed will determine how much aggregate (or stone) is exposed. While there are different variations of each (such as color), salt and pepper, sporadic rock, medium rock, or heavy rock exposed are the most common.

Salt & Pepper

Heavy

Medium

Copyright © 2025

Aggrecon Specialties Incorporated. All Rights Reserved.